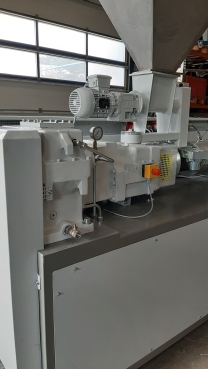

New twin-screw extruder STK-HMG 65-22

Twin screw extruder for the production of PVC pipe and profile.

Available extruder:

STK-HMG 65-22

- Quality made in Austria

- High-quality components from leading European manufacturers

- Design and equipment to customer specifications

- Many options already available in the basic version

Technical data:

Screw counter rotation: 65mm/22D

Output capacity-pipe: 200-220 kg/h

Output capacity-profile: 150-180 kg/h

Max. speed: 61rpm

Barrel heater: 18,8kW

No. of barrel cooling zone: 3

Motor drive: 30kW

Dosing feeder: 0,75kW

Weight: 2200kg

Vacuum pump: 0,75kW

Adapter 0,75kW

Tooling die zones: 1x adapter zone, 5x tool zones

Dimension: length: 3100mm, width: 1300mm, height: 2300mm

- user friendly touch screen extruder control (18,5 zoll wide screen) with many functions like

- for example:

- haul off control by analog interface

- synchro drive by main motor dosing device and haul off

- receipt storage

- Online access with web browser or mobile phone

- Data recording of the most important process parameters with data backup and export for Excel or open office

- precise PID temperature control for cylinders and tool zones with auto-tuning

- Weekly timer for automatic preheating of cylinders and tool zones